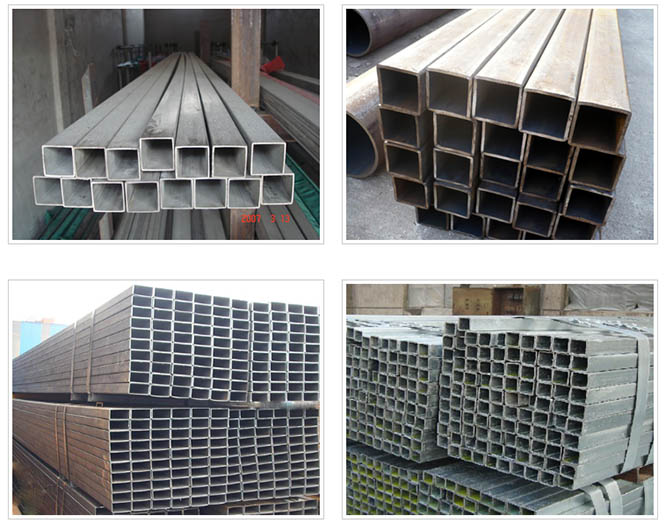

Hollow Section

- 0 Views

As per ASTM A53, BS1387, DIN2244, GB/T13793, GB/T3091, GB/T 6728, GB/T6725

Surface treatment: galvanized or coated with oil or black color to prevent rusting

Length 5.8M /6M or as per customer’s request. Minimum order: 50MT per size

| Commodity | Size | Size tolerance | Thickness | Length Tolerance |

| Hollow Section | 16×16~25.4×25.4 | ±0.15 | 0.7~2.0 | +50mm |

| 30×30~50×50 | ±0.20 | 1.0~3.0 | +50mm | |

| 60×60 | ±0.15 | 0.7~2.0 | +50mm | |

| 100×100--200×200 | ±0.60 | 3.0~6.0 | +50mm |